|

Solar energy utilization Solar Cell and Modules Our first-class professional technical talent and advanced production and testing equipment allow us to manufacture crystalline silicon solar cells and cell modules characterised by their high efficiency, high power, high reliability and non-pollution. We are one of China's largest solar cell and cell module manufacturers. Our mono-crystalline and polycrystalline PV modules consist of high efficiency PV cells, aluminium alloy, EVA film, toughened low-iron content glass and TPT.

|

|

|

Solar Backsheet HS CODE:3920 6200 00 Product Application: Market Location: Our annual production capacity is 100 million square meters, with the sales volume of 76.7 million meters in 2022 (including the export of 3.50 million meters). We have cooperation with the global head customers of the direct upstream components of the solar module. The export target markets of us are the overseas factories of domestic PV solar module company and some large-scale regional and international solar module factories. Quality level: Export policy restrictions: None Key Types: |

|

|

| Hydrogen energy utilization Hydrogen liquefaction system

Technical features:

Hydrogenation station

Technical features:

Applications:

|

||

|

Fuel cell system Parameters: Fuel cell system output power:1kW~110kW; Working temperature: -30℃~55℃; Rated efficiency:42%; High power density; Well integrated; Adapted to high and low temperature; Quick response. Application field: It can adapt to the marine, automotive and fuel cell power etc. |

|

|

|

||

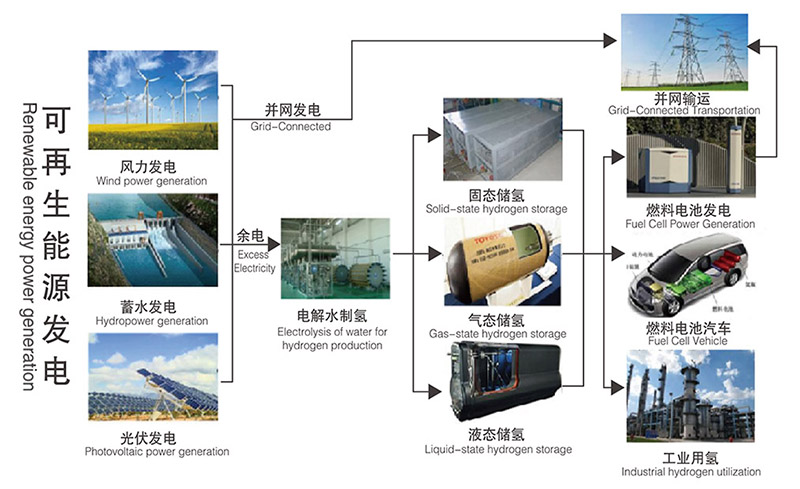

System functions: Renewable energy power generation - water electrolysis - hydrogen storage - fuel cell power generation -utilization of electricity/ hydrogen / oxygen. The operation mode coordination strategy and control technology of wind, light and other renewable energy and hydrogen energy systems based on multi-objective optimization control theory have been realized by the intelligent sensing and off-grid multi-energy control module. The discrete-continuous hybrid control method is used to realize the coordinated decision of the top energy state conversion and the continuous control of the bottom units. Application field : It can adapt to the hydrogen storage in remote areas, border posts, offshore islands, and other application scenarios. |

||

Hydrogen Production from Renewable Energy and Energy Storage System Parameters: Shape size: standard military shelter, box frame and modular structure; Main components: photovoltaic unit, fuel cell unit, energy storage and energy management unit, stealth power station unit, each unit and its power demand is optional; Working mode: realizing the overall power supply, unit independent external power supply, and multi power supply system parallel expansion; Output characteristics: single-phase AC, three-phase AC, DC, selected according to demand.

|

|

|

Application: It provides a safe and reliable battlefield energy supply for command information system, intelligence reconnaissance system, combat equipment system, and base life system, and for future intelligent warfare. Functions and advantages:

|

|

|

Application characteristics:

|

|

|

Key Components Fuel cell stack Parameters: Fuel cell output power: 1kW~ 110kW, Power density:2.6L/W, Low temperature start: -30℃without auxiliary heat source, adapt to the vehicle vibration environment , and the test performance has reached the domestic leading level. Application field: It can adapt to the marine, automotive and fuel cell power station, etc. |

|

|

Central controller Parameters: Channel number : nearly 80 physical resources ( including voltage, current, temperature, digital quantity, switching quantity, PWM output, etc. ). Measurement and control accuracy : < 0.5 %. Electromagnetic compatibility: following GJB, GB and ISO related test requirements. Low temperature and low pressure environment : -40℃, 5.5 kPa. Protection level : IP67 Application: The core controller is developed based on TI's DSP or Freescale and Infineon processors. The controller has the advantages of rich measurement and control resources, complete interface types, high reliability and mass production. Interface embedded driver library and related upper calibration software can be provided. |

|

|

Single-chip voltage detector for stack Parameters: Measurement and control channel : single board 30 channels, extensible. Measurement and control accuracy: <1%. Single-chip measurement range : 0V ~ 2.5V. Communication : Follow CAN2.0B protocol. Working voltage : 18V ~ 32V. Working environment temperature : 0 ℃ ~ 50℃. Size : 230mm×180mm × 80mm. Application: Single-chip data monitoring of fuel cell stack. |

|

|

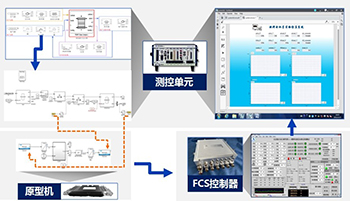

Fuel cell system simulation platform System functions:

|

|

|