| |

|

|

Energy Conservation Transformation for Industrial Furnace

This product is mainly used in the petrochemical industry. it adopts a unique process flow and makes full use of the waste heat and excess pressure resources in the chemical device area to heat the combustion air in the cracking turn ace and the combustion air at the bottom of large negative pressure heating furnace. The normal operation of the system does not occupy additional energy consumption because it is a pure energy-saving technology. It saves fuel and improves energy utilization while reducing carbon emissions. realizing energy saving and emission reduction. without adding any additional energy consumption, and reducing fuel consumption by 1.5%~5%.

Technical characteristics

| Select waste heat |

Select the heat source with waste heat as the heating medium, and do not select the useful heat source as the heating medium, such as low-pressure steam, various condensates,industrial sewage, furnace drain contamination, quench water and other mediums. |

| Bidirectional energy saving |

The air is heated, saving fuel and making the cracking furnace device energy saving; the waste heat is cooled, and the secondary energy is no longer consumed for treatment, making the device that provides the waste heat source also energy-saving. |

Pure energy-saving |

In principle, the energy-saving system operates normally without external power consumption. Use the negative pressure allowance reserved in cracking furnace to realize the transmission of gas path: use the pressure energy stored in waste heat medium the liquid path. |

| Flexible |

The operation of energy-saving system is flexible, which will not affect the normal

operation of the original device system, with easy operation and maintenance and long service life. |

Application

It has obtained a patent in China and has complete the ethylene production scale of 15 million tons/year by using the patented technology. There are 332 cracking furnaces in total, saving more than RMB 1 billion per year.

|

|

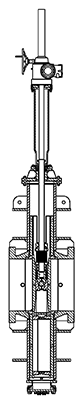

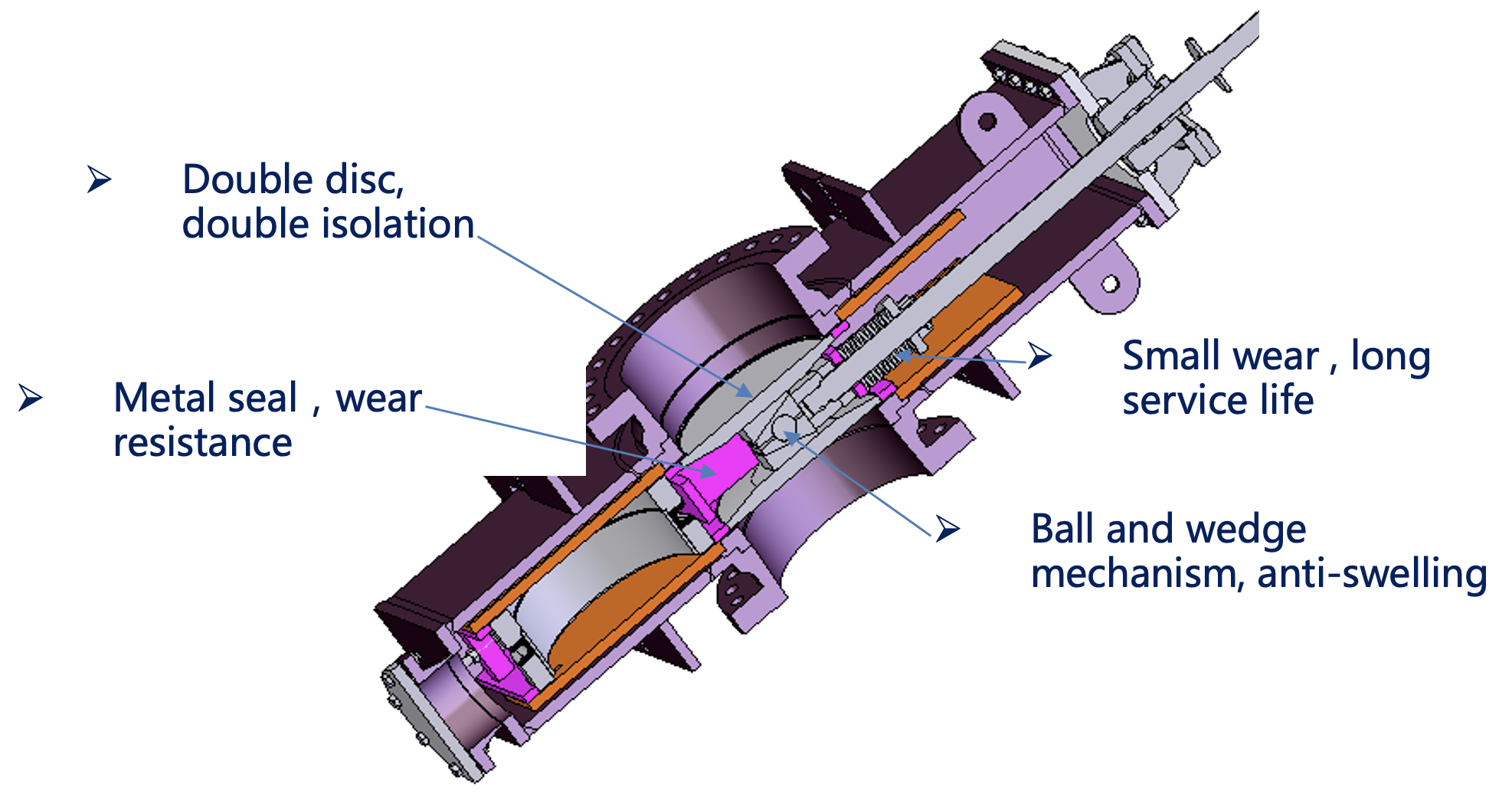

Transfer Line Valve for Ethylene Plant

This product is the earliest localized cracked gas valve in China, with the maximum caliber of 48 inches, and the cumulative production exceeds 300 cracked gas valves and the cumulative maintenance also surpasses 300 cracked gas valves, with the key technology reaching or leading the advanced foreign level.

Product series

|

|

| Single gate valve |

Double gate valve |

Cracked gas large valve working conditions characteristics

- Two media cracked gas, steam)

- Cracked gas coking properties

- Large caliber

- High temperature

- Low pressure

Application cases

- Zhongyuan Ethylene 20"+6" linkage valve

- Huizhou Ethylene 36" 24" valves

- Wuhan Ethylene 32" pneumatic valve

- Wanhua Chemical Group 24" decoking valve

Technical advantages

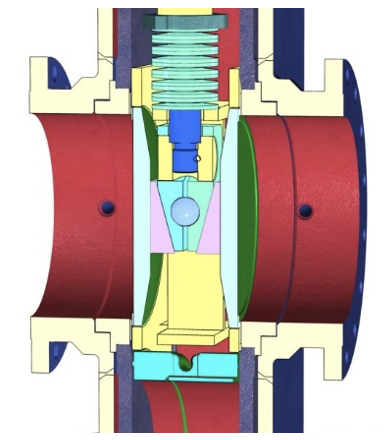

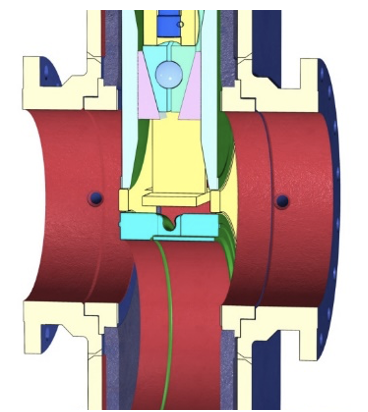

Three-position seal, good anti-coking performance

|

|

|

|

|

| "OFF" position |

|

Middle position |

|

“ON” position |

| *Forced sealing, reliable sealing |

|

*Floating seal

*No gap in the internal part guide and there is isolation of the flow path from the valve cavity |

|

*Elastic seal

*Direct piping, no pressure loss |

| |

|

|

|

|

|

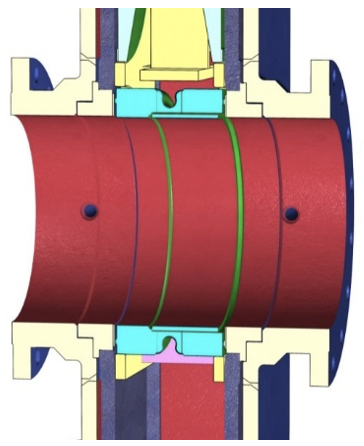

| The structure is split seat and one-plece stem, which is easy to manufacture and maintain |

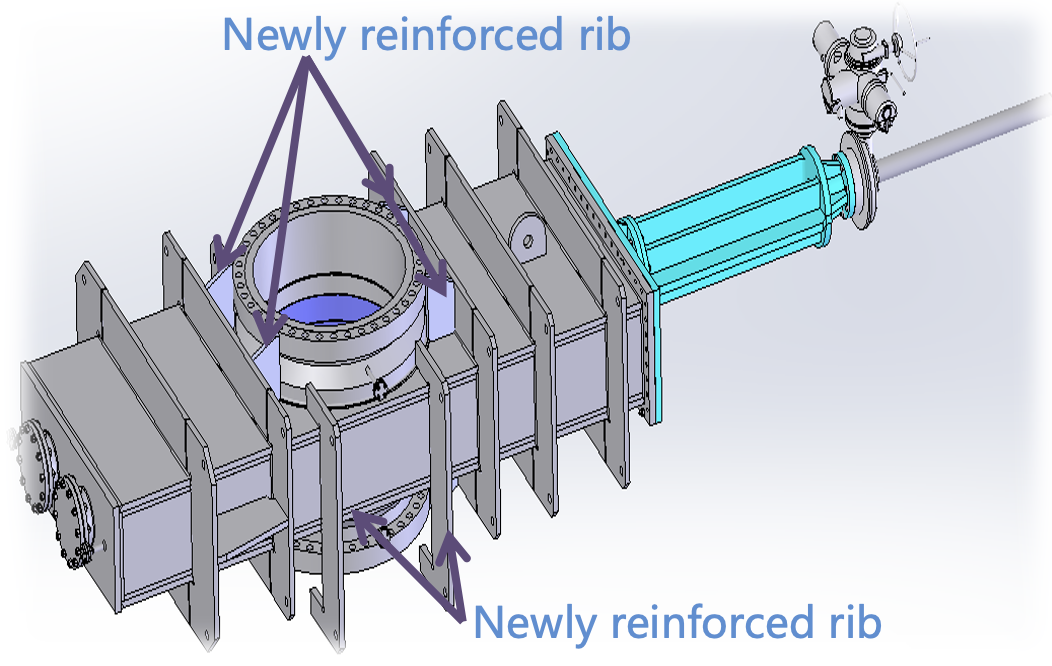

Optimized fascia

*increase the stiffness of the valve body to improve the payload resistance and ensure the sealing performance |

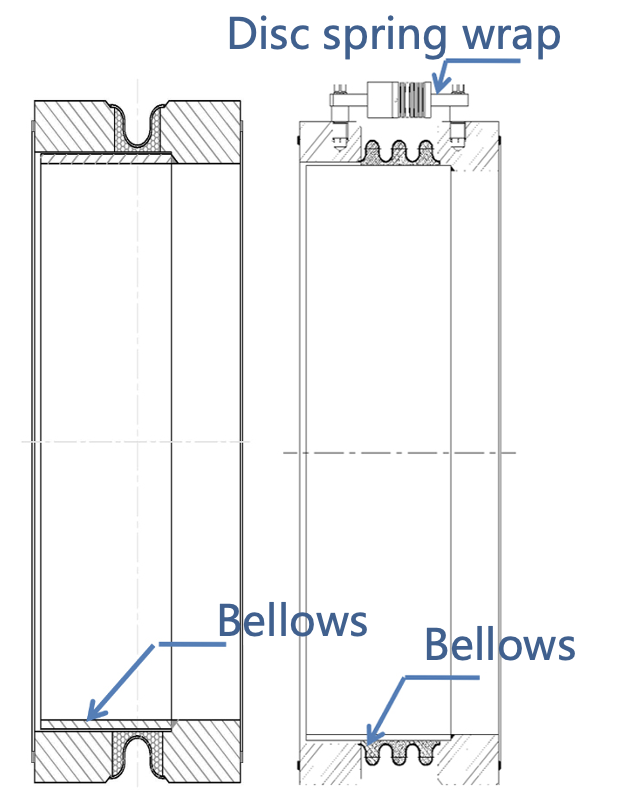

Expansion joint improvement

*Adopt three-wave design and set disc spring package to improve sealing effect |

Certifications and relevant qualifications

- Environmental engineering design certificate

- Manufacturing license of measuring instruments

- Permit for the design of pressure vessel

- Permit for the manufacturing of pressure vessel

- Permit for the manufacturing of special equipment

- Certificate of ISO9001 Quality Management System

- ASME Boiler and Pressure Vessel Code Certificates

|

|

Post-pump Filtration System of Emergency Cooling Oil

It is composed of a cyclone hydraulic separator, a stationary device, a connection line and a valve. The cyclone hydraulic separator is mainly composed of shell and wear-resistant lining; the stationary device is an automatic scraping filter, mainly composed of driving device, transmission mechanism, screen module and shell.

Technical characteristics

- The inlet of the cyclone hydraulic separator is designed with rectangular worm shell and inclined guide plate, with high separation efficiency and low pressure.

- Enable to realize solid-liquid separation with large flow rate and low density difference

- Wear-resistant treatment technology for easy-wear areas, long equipment life

- Stationary device with Johnson screen, high filtration accuracy

- Quick-open flange is set at the decoking port of the stationary device which is convenient for decoking and reduces labor intensity

- The system cleans out the coke particles are dry powder

|

|

|

| |

|

|

| Application cases |

|

|

| End-user |

Size(NPS) |

Design Temperature/℃ |

Design Pressure/Mpa |

Order Time |

Delivery Time |

Project |

| SINOPEC-SK(WUHAN) Company Ltd. |

48″/24″ |

425 |

0.2 |

2019.2 |

2019.12 |

Ethylene Renovation Project |

| Sanjiang Chemical Co., Ltd. |

36″/30″/24″ |

425 |

0.47 |

2020.8 |

2021.6 |

1000000 t/a EO/EG Project |

| Tsinghe Chemical Co., Ltd |

54″/42″/36″ |

590 |

0.35 |

2022.1 |

2022.9 |

1600000 t/a Ethylene Project |

| SINOPEC Tianjin Company |

60″+14″/36″+10″/32″/24″/18″/16″ |

425 |

0.45 |

2022.1 |

2022.10 |

1200000 t/a Ethylene Project |

| SINOPEC Hainan Company |

48″+14″/28″ |

425 |

0.45 |

2022.2 |

2022.7 |

1200000 t/a Ethylene Project |

|

| |

|

|

Decoking System for Quench Oil in Ethylene Plant

This product is mainly used to remove coke particles from the emergency cooling system of ethylene plant, which consists of the pre-pump filtration system of emergency cooling oil and the post-pump filtration system of emergency cooling oil This product has passed the ISO9001 quality management system certification and obtained the qualification of pressure vessel design and manufacture.

Pre-pump filtration system of emergency cooling oil

It consists of main filter, sub-filter, connecting pipeline and valve The main filter is an automatic scraper filter, mainly composed of drive device, transmission mechanism, screen module and shell; the sub-filter is a basket filter, mainly composed of shell and basket screen.

Technical characteristics

- Stable differential pressure between the inlet and outlet of the main filter to ensure long and reliable operation of the system

- Innovative seal design for reliable sealing of main filter rotating shaft system

- Reasonable shaft system design ensures smooth operation of the main filter under high temperature and high pressure severe working conditions

- Overcome the shortcomings oftraditional basket filters that a are easy to block and difficult to clean, improve production efficiency,reduce maintenance costs and reducel abor intensity

|

|

|

| |

|

|